The development and making of our F1 car was a detailed and collaborative process that combined creativity, engineering, and innovation. Starting with initial concept sketches, we used CAD software to design a sleek, aerodynamic model that met all F1 in Schools regulations. We ran CFD simulations to refine airflow and reduce drag, making continuous improvements to enhance performance. Once the design was finalized, we manufactured the car using CNC machining and carefully hand-finished each part for precision. After assembling and testing the car, we made final adjustments based on performance data. The result is a high-performance, lightweight, and visually striking car that showcases the teamwork and dedication of Nitro Ninjas.

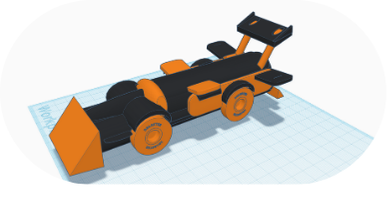

Tinkercad Model

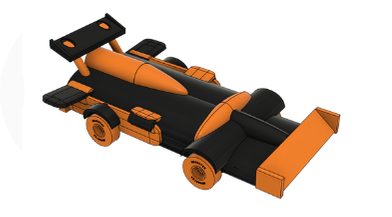

2nd Prototype

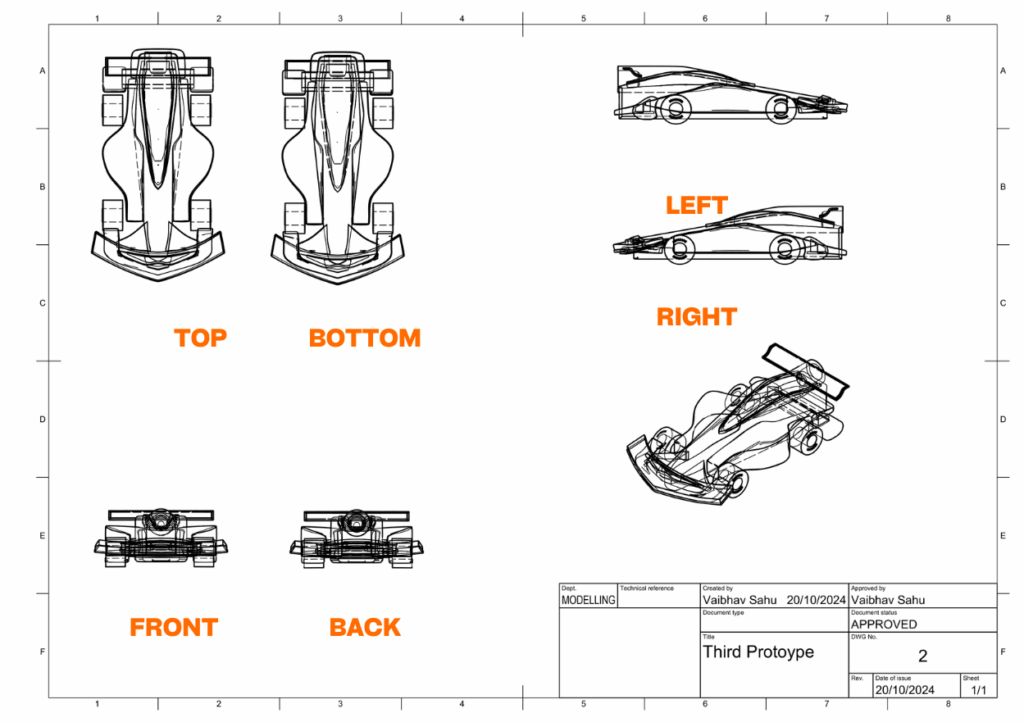

3rd Protoype

Inspiration

Main Goal: Maximizing Aerodynamics

The inspiration of our car is based on the world’s fastest autonomous car (Image 3). This would become our base model for our F1 car.

Our first goal was maximizing drag force and making sure our F1 car stays on the track for stability no matter the speed. We first thought on adding a spoiler to achieve the above goal but later decided on a unique way of adding a gas canister on top of the car and a barrier on the front to do the same yet better.

Our second goal is to now work our way to speed arrangements and to improve the overall design of this car. We wanted the car to cut through the air as much as possible. We agreed upon the middle body and the rear as in the figure to allow as much air to reduce air resistance. This settles it for speed in our car.

Our third goal is the finale of our research and development. It was time to work on the intricate and delicate details of the car that would make it win the race in style. We gathered more information about the tiniest of details to escalate the chances of success in the race for us.

Design Process

Portfolio, Sponsorship Presentation, Posters and most of the graphics.

Making a base/rough model to help us understand how to make our car.

Further improvement on design and finishing our first prototype.

Assisted us on the creating the finishing designs for the car and development of our marketing posters

TESTING

Testing the Aerodynamics of our car is a crucial factor in our journey through this competition. It allows us to understand where air cannot flow properly and what parts of the car to edit to ensure smooth racing with maximum efficiency.

We have used Ansys Discovery 2024 R2 to test our car. It is one of the top software for CFD (and other) simulations. Below is our first test in which the car has relatively proper aerodynamics. As seen in the animation, air has the property to take the shape of the object that goes through it. Our special front bumper does a great job in allowing air to flow over the car, which will prove beneficial in the event.

AERODYNAMICS:

The scientific examination of air interactions with moving objects, playing a vital role in our F1 Model. Understanding these principles is essential for optimizing vehicle performance, efficiency, and safety.

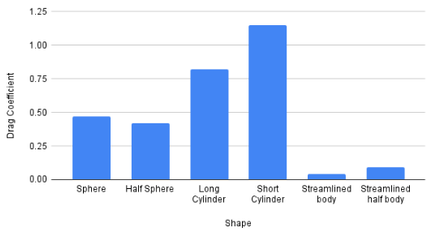

DRAG COEFFICIENT:

A number that measures how much drag or resistance an object experiences when moving through a fluid, like air or water. It depends on the shape.

IMPORTANCE OF AERODYNAMICS IN F1 CARS

The car with better aerodynamic design will likely experience less drag, allowing it to reach higher speeds more quickly. A streamlined shape can significantly impact performance.

NEWTON’S SECOND LAW OF MOTION

(F = ma) – Also by Isaac Newton, this law means the force on a car equals its mass times acceleration. So, a lighter F1 car with a powerful engine accelerates faster.

Aerodynamic Drag (Bernoulli’s Principle)

Daniel Bernoulli discovered that faster airflow creates lower pressure. F1 cars use this to stay glued to the track (downforce), helping them corner at crazy speeds!

Orthographic drawings